🔧 Power Meets Precision: Control Your Motor Like a Pro!

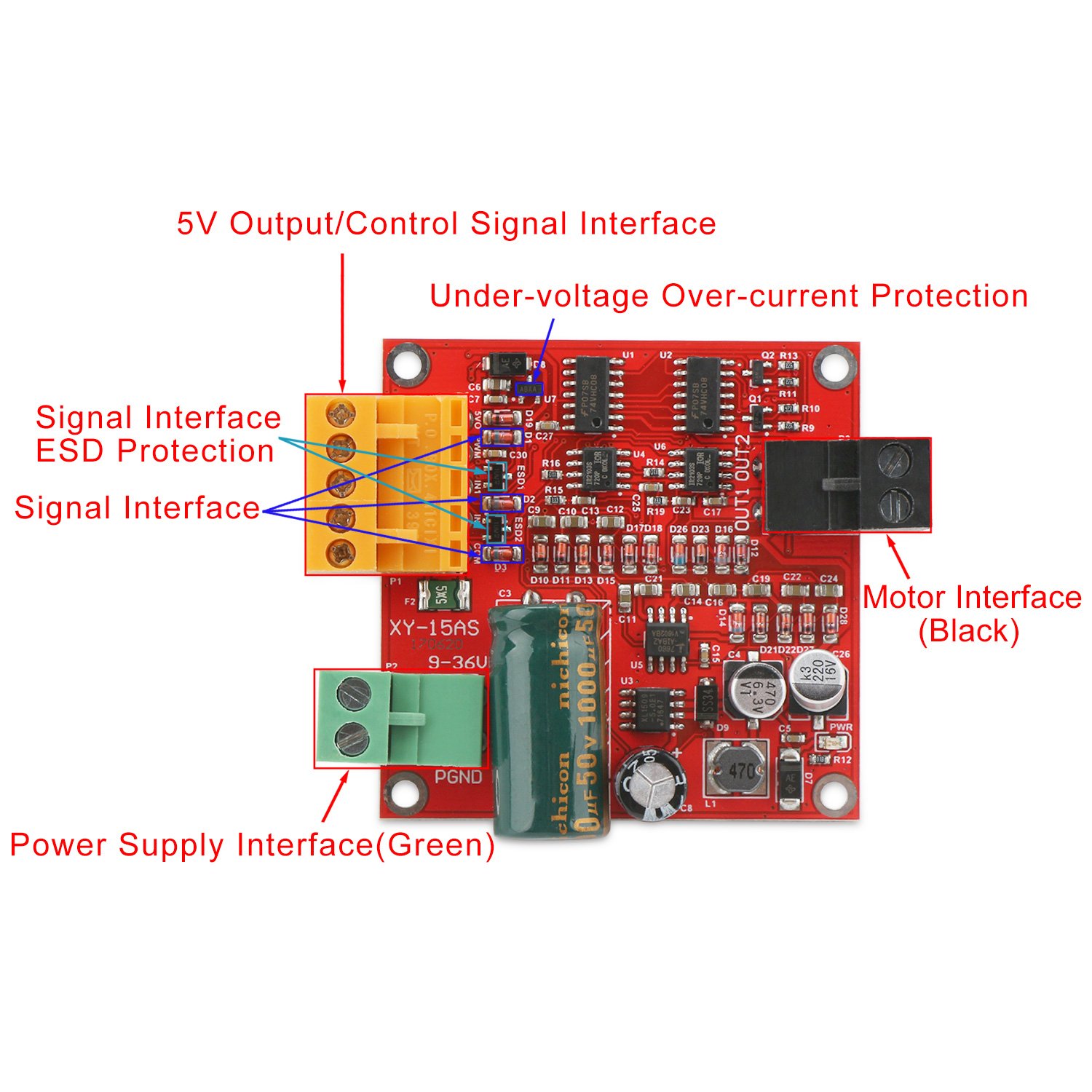

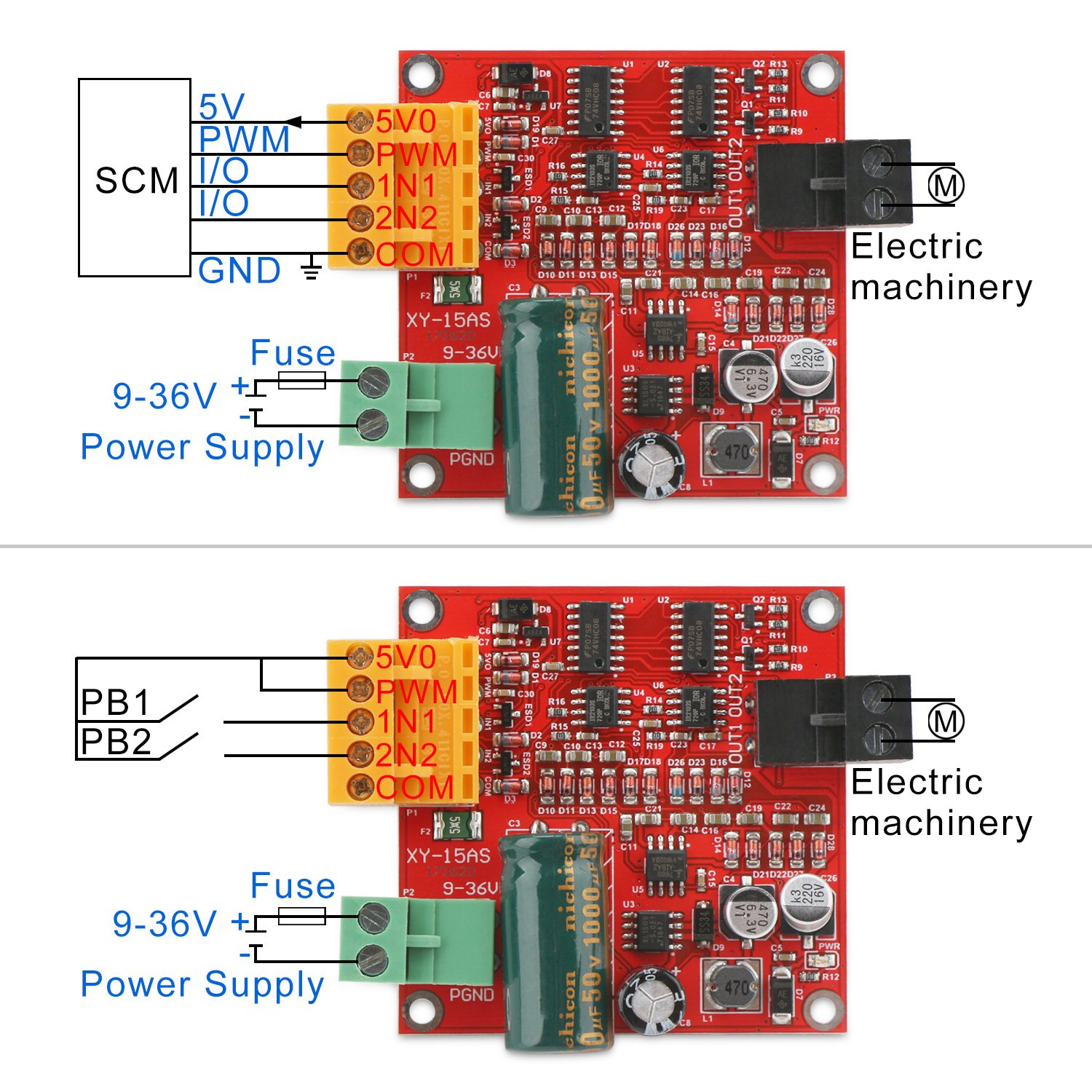

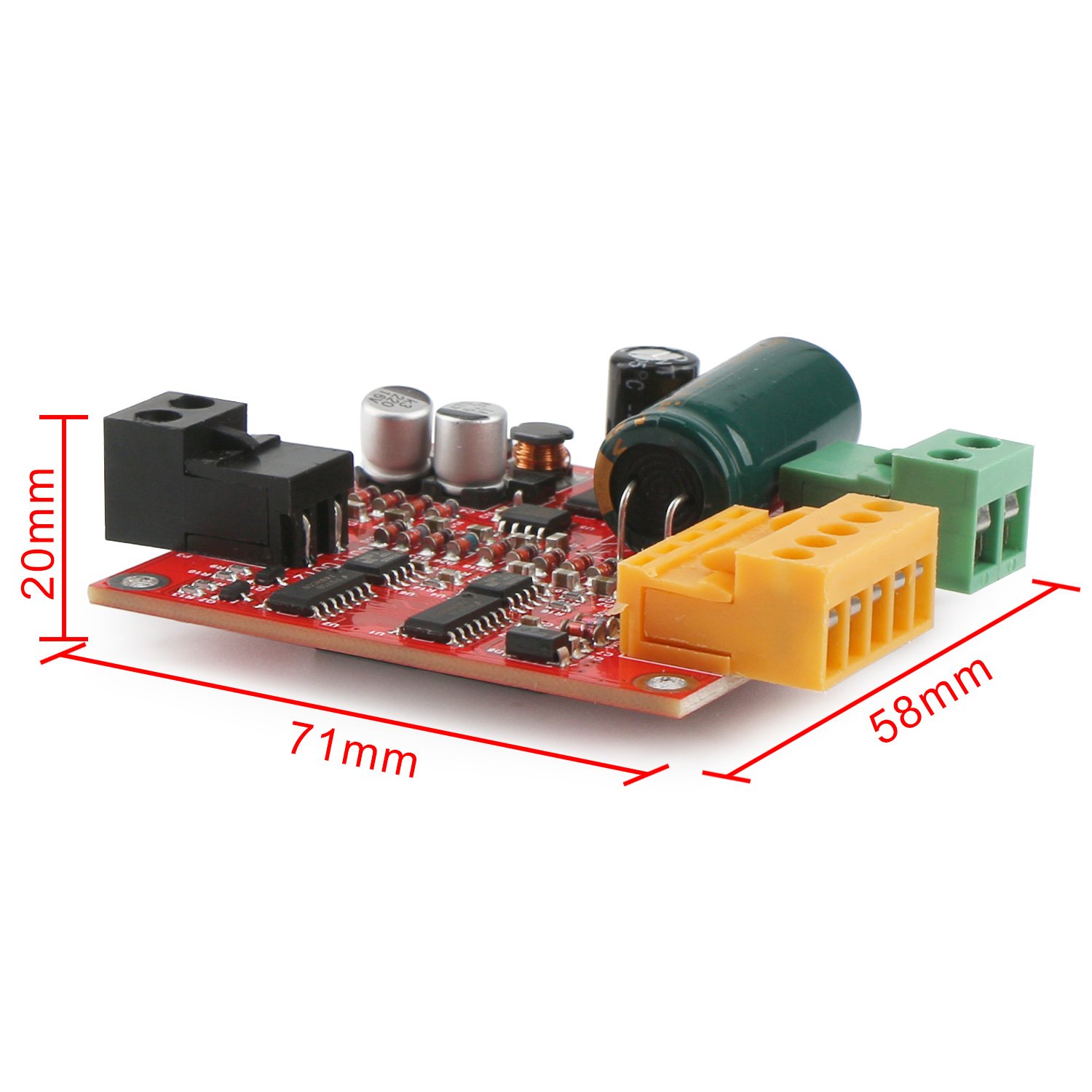

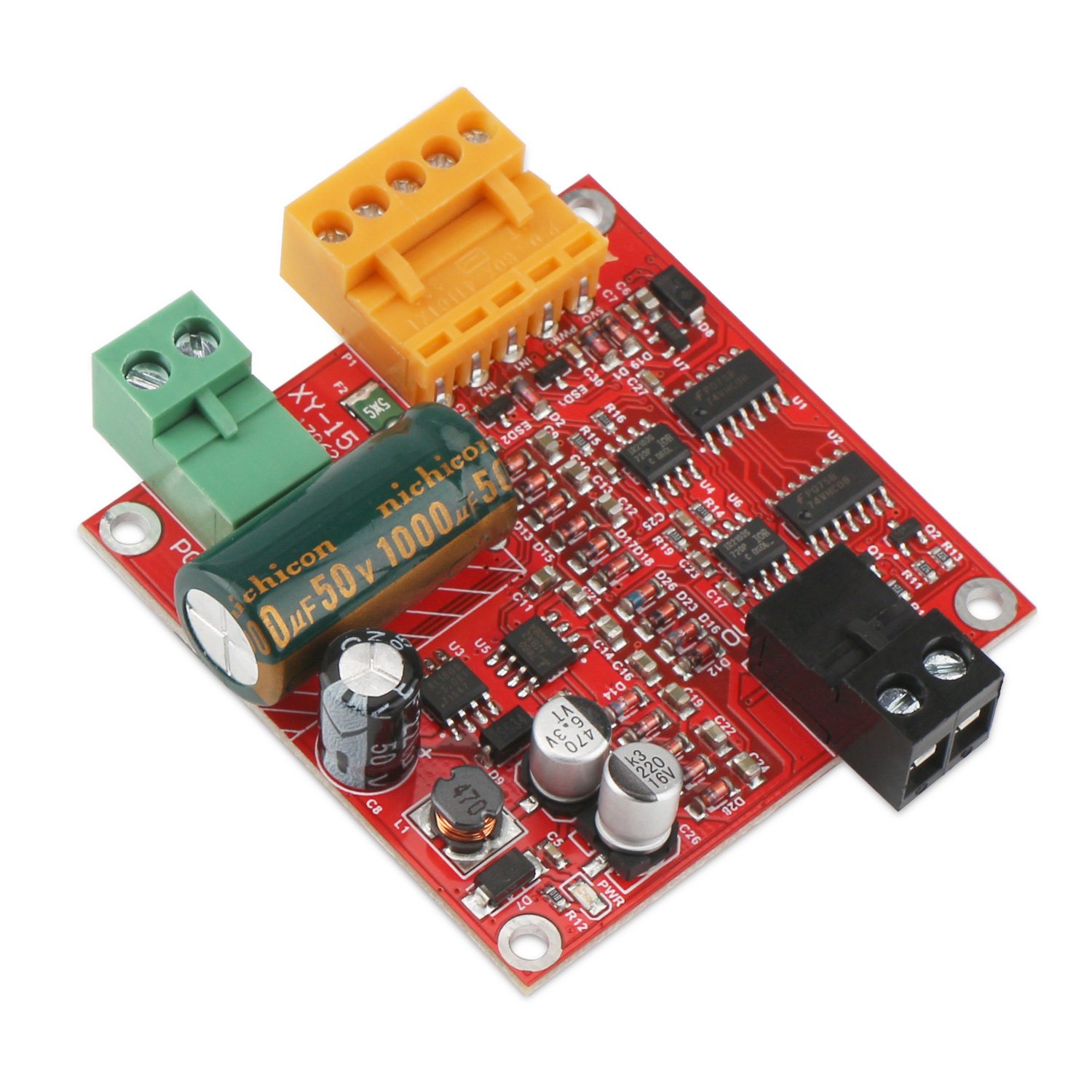

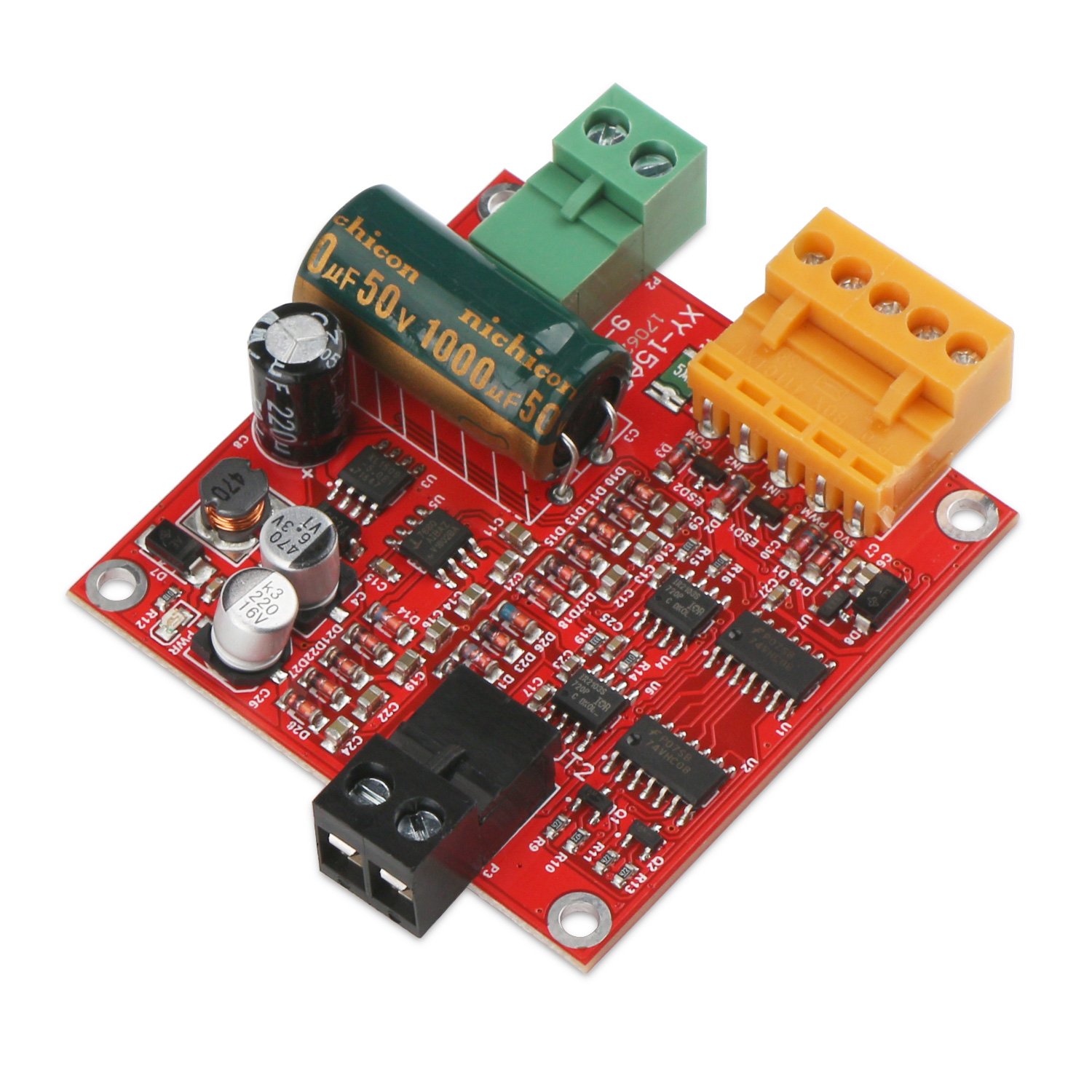

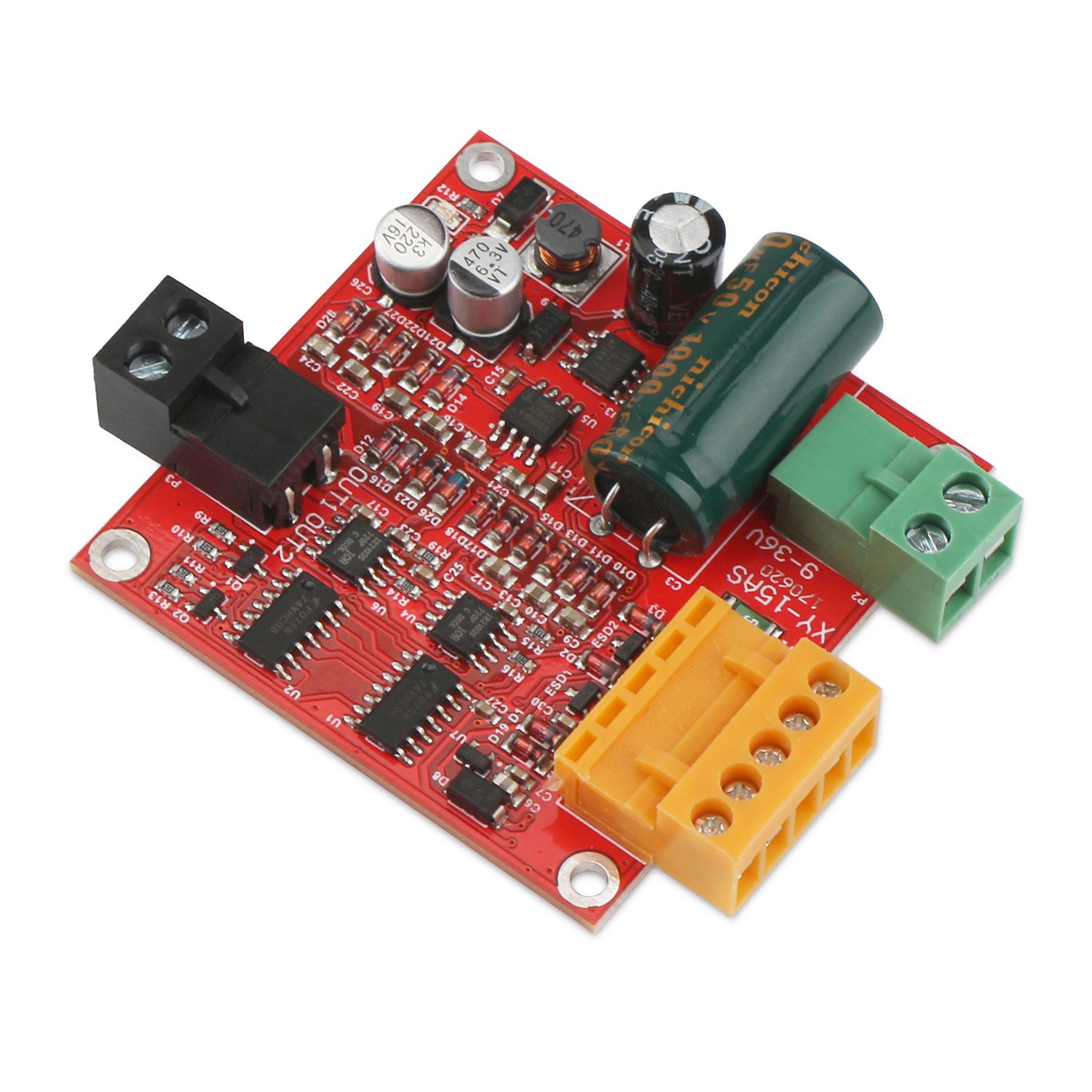

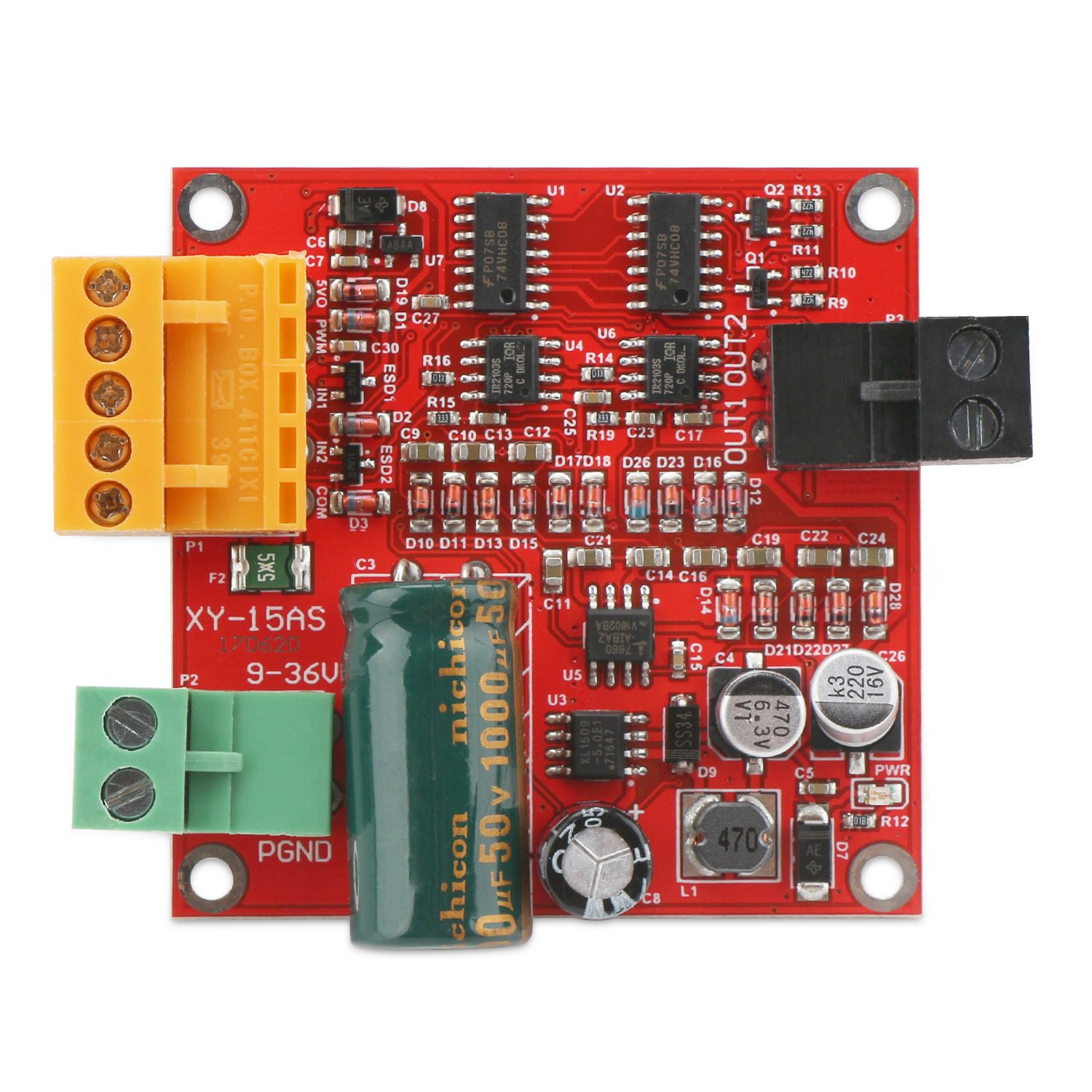

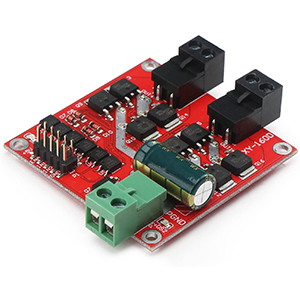

The DROK Linear Actuator Control Board is a high-performance DC motor controller designed for industrial applications. With an input voltage range of DC 9-36V and a robust 12A current rating, this module offers precise PWM speed control and multiple operational modes, all while ensuring safety with built-in protections. Its compact design makes it an ideal choice for professionals seeking reliability and efficiency in motor control.

| Manufacturer | DROK |

| Part Number | 200337 |

| Item Weight | 1.41 ounces |

| Package Dimensions | 5 x 2.95 x 1.54 inches |

| Is Discontinued By Manufacturer | No |

| Size | PWM Motor Driver Controller 12A |

| Batteries Included? | No |

| Batteries Required? | No |

D**Y

Saved mechanical engineering senior design project

Worked great for what I needed. Used as a directional controller for a 12V DC motor and also tried it with my 12V DC linear actuator. Did exactly what I wanted on both. Great product for the money!

M**G

Great product, had an odd issue with some

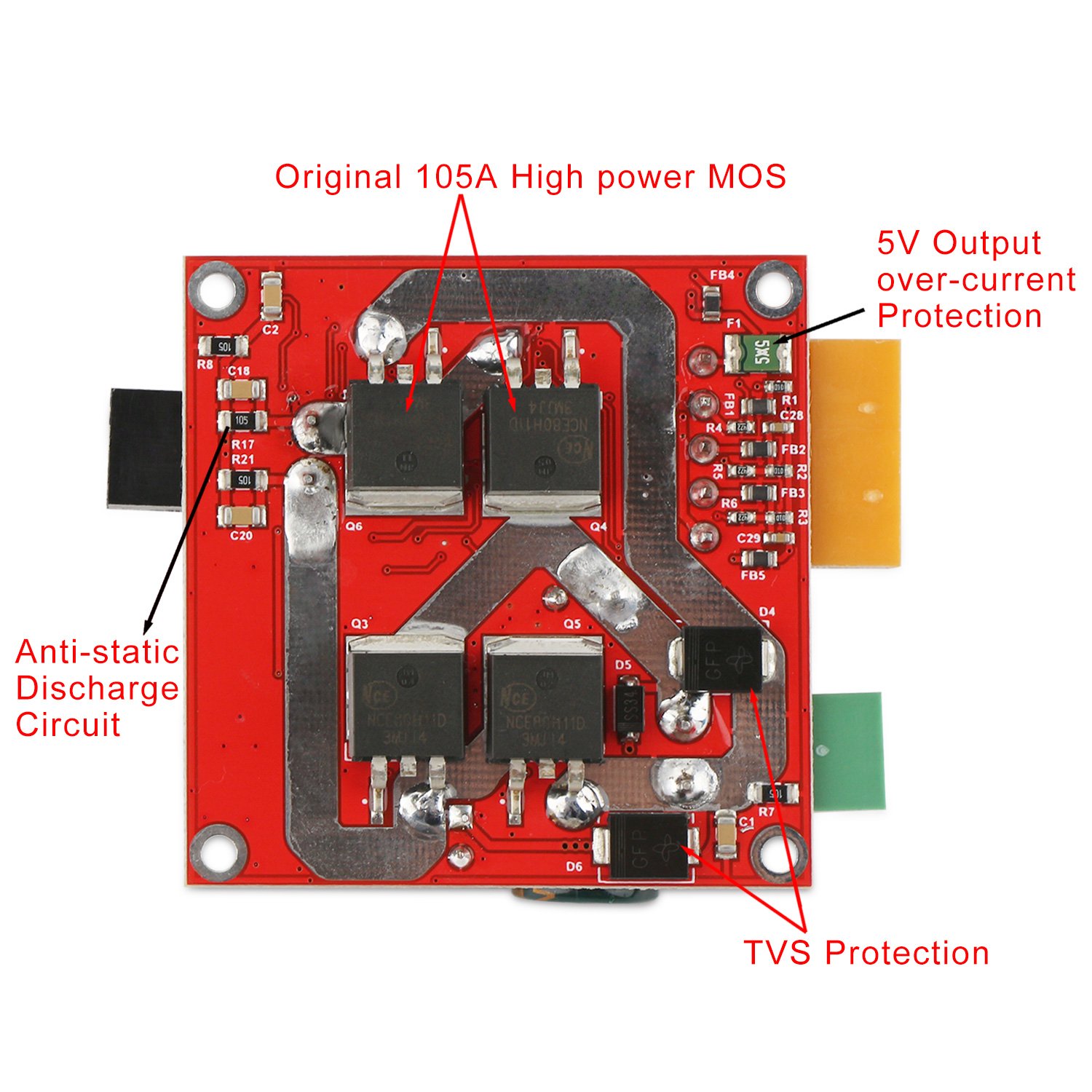

The first two I ordered worked great and implementation doesn't get much easier, simple PWM and two 5v digital pins is all it takes to get it working.Headers on these boards are well made and detachable which helps a ton, the 5v rail is a buck converter, so no more of those 7805 regulators heating up your project and the accuracy is phenomenal! Plenty of ESD and BEMF protection and very beefy soldered traces for the MOSFET IO. PWM control is very precise and the MOSFETs don't heat up while switching (good driver circuitry).That being said the second two were obviously not inspected... I still have yet to find the source of the failure on the boards, but with all four connected in parallel, separate linear actuators connected to each, all 5v and grounds paralleled, PWMs all paralleled and input pins going to arduino digital outputs; the 5v buck converter on the most recent two began smoking and nearly caught fire.I'm sure this is a fluke incident but just to be safe check your buck converter diodes before plugging into DC power, this one was receiving 15v filtered DC. After taking a look at the boards it appears that component FB4 (Ferrite bead) for filtering blew to pieces and the two diodes in the buck converter were 0 Ohms in either direction!

A**M

stays cool at 10-15A

original review Reviewed in the United States on May 26, 2019I used these to drive DC motors that draw about 10A continuously and up to 15A. Following DROK's advice I added heat sinks. They don't even seem to warm up above room temperature, even at 20kHz PWM frequency. The boards appear to have good build quality compared to similarly-priced Chinese H-bridges: no messy soldering or recycled components. The instructions are clear even if a few details are lost in translation. I would buy these again.update 2024:welp 5 years of heavy use later and the thing finally kicked it. pretty sure I was occasionally exceeding the max current as well. rip, drok h-bridge; you were a great cheap motor controller. I'll be replacing you with an identical twin.

M**Y

Very nice implementation

This worked the first time I hooked it up. Instructions are included and easy to follow. I had tried using a cheaper brand and did get some speed control, namely off and full bore. This chip ramps up very nicely as the PWM signal increases. I would recommend this chip if you need DC motor control.

A**Y

What's left of my DROK motor controller

Bought a two-pack, one to use as a spare. The first one worked for a while then the tracks burnt. Guess that was my fault. The spare one also worked for a while then stopped. When I put it on my test bench the power supply kept shutting down. A power device such as this should be more robust and better designed. Some of the SMT components fell off before I could install it. Best thing about it was the connectors which I salvage. Will try another brand or use a relay driver instead..

C**E

A Solid Option for Robots

Excellent motor drivers. Optoisolation really helped the voltage spike problems my robotics team was facing when using high torque motors in frequently changing circumstances. Terminal blocks separate to make connecting lots of wires a breeze. Power indicator light helped tremendously with troubleshooting power issues when in a system.

R**.

Motor driver, a bit of logic that's not well documented

There isn't a lot of document on how the signaling works on this board, so here is the detail:PWM/IN2/IN1:000 / 100 : Break state, both output are grounded001 / 101: Forward drive, 1 on PWM cause the high side MOS to drive, 0 cause high side to float010 / 110: Reverse drive, 1 on PWM cause the high side MOS to drive, 0 cause high side to float011 / 111: Float state, all output are floatingSimple usage guide:Attach PWM to the PWM pin on Arduino and set a duty cycle for the speed desiredIN1/IN2 can be set to either 01 or 10 for forward or reverseIf you want the motor to brake, set IN1/IN2 to 00If you want the motor to spin freely, set IN1/IN2 to 11

W**Y

Five Stars

The speed controller was nicely built and a bargain, shipping was fast :).

Trustpilot

5 days ago

3 weeks ago