Customer Services

Copyright © 2025 Desertcart Holdings Limited

Full description not available

S**Y

A robust and highly readable introduction to Lean for the veterinary leadership team

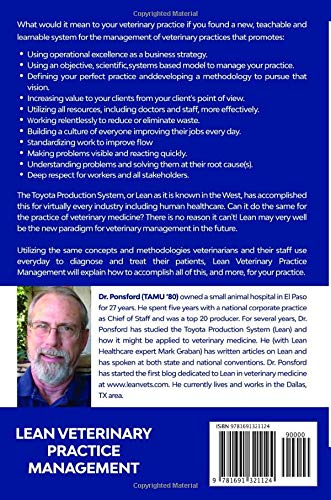

I don’t want to be accused of using hyperbole here, but Dr. Ponsford has done the veterinary profession a great service in writing this book.As described in chapter 11 the origins of Lean and the Toyota Production System can be traced to the rapid and successful ability of the US government and manufacturers to scale up for wartime production during the early 1940s using a system developed by the War Department known as Training Within Industry (TWI). To those in the known the rest of the Lean story is history as they say. To those who don’t know, Dr. Ponsford does an excellent job of briefly describing the origins and evolution of this powerful management philosophy while also providing in-depth content to allow even complete neophytes to put some of Lean’s most powerful principles to work in a matter of days.In the preface Chip sets out his three clearly defined target audiences for this book:1) Those in the veterinary field who have never heard about Lean or the Toyota Production System (TPS)2) Those who are considering starting their own practice but are apprehensive about management and leadership aspects3) More seasoned owners who might benefit from a different, viable mindset that can add new perspectives to older practice management philosophiesSeeking to appeal to all three of these audience groups is clearly an ambitious goal, especially given the size and scope of both our industry and the Lean philosophy itself. That said I can confidently say that this book as plenty to offer to all three audience groups as well as many more including those like myself who have prior knowledge of and experience with the system but are looking for pearls to apply its use to veterinary practice management.In addition to covering the history and philosophy of Lean and the TPS, Chip provides detailed coverage of a variety of Lean tools such as value stream maps, root cause analysis, 5S, standardized work, visual management, error proofing, the andon cord and more. Many of these tools can be quickly deployed but should also be used again and again in PDSA (Plan Do Study Act) cycles in the constant striving to reduce waste and improve value that is at the heart of the Lean philosophy. Indeed, the author, like other Lean gurus, cautions the reader not to simply look for the right tool but rather embrace the entire Lean philosophy including the fact that perfection may never be reached but certainly should be sought after.One facet of this book and the Lean philosophy in general that particularly appeals to me is the concept of nemawashi which loosely translates to consensus building. Lean acknowledges that leaders need to “work with front line personnel… because they know better” about the nature, causes and solutions to front line problems. Indeed, the author goes on to state that “in Lean culture, there is dep respect for the workers.” A concept that was truly ahead of its time when first developed in post-war Japan and still seemingly ahead of its time in many circles of Western management.I feel that I must address that fact that I believe that critiques about this book making recommendations to use simple tools, such as post-it notes, are naive and ill-conceived. As the author points out in the book this very system is credited, in large part, with Toyota’s rise from a small domestic truck manufacturer in Japan to a global powerhouse.So, what’s wrong with the book? Not much really. I think there is certainly scope in the future for a second edition or a stand-alone workbook with even more ideas for implementing Lean and a deeper dive on some of the tools, but that doesn’t take anything away from the comprehensive nature of the first edition. I don’t think Chip is pretending to make this book out to be the be all end all of Lean in veterinary medicine; rather a solid introduction, a conversation starter, and quick start guide. For interested parties he does provide an incredibly useful and comprehensive recommended reading list that could be consumed by the interested student over a period of years (he lists some 30 books on the topic) should they so desire.To conclude, Lean has had an incredibly successful run in a variety of manufacturing environments for over 70 years now and has a near 20-year history of successful implementation in a diverse range of human healthcare endeavors. With the help of this book, its author and others like him we may just be on the tipping point of veterinary medicine finally taking this discipline seriously and likely transforming our industry for the better. Simon R. Starkey BVSc, PhD, MBADiplomate, American Board of Veterinary PractitionersMember, American College of Epidemiology

B**G

Not the content I expected for a Vet practice management help book.

Wasn’t what I expected. Methods are extrapolated from the Toyota Production System. It’s ideas and methods are antiquated. Charts, bulletin boards and post it notes for organizational meetings.

Trustpilot

1 month ago

2 months ago